Winchester Powder Can Be Fun For Anyone

Wiki Article

Some Known Details About Imr Powder

Table of Contents3 Easy Facts About Hodgdon H4350 ExplainedMuzzleloading Powder Things To Know Before You Get ThisAccurate Powder Fundamentals ExplainedThe 5-Second Trick For Hodgdon H4350

The aeriform propellant decays right into simpler particles in a surrounding fizz zone. Power is launched in a luminescent external fire zone where the easier gas particles respond to create conventional combustion products like heavy steam and also carbon monoxide gas. The foam area works as an insulator slowing down the price of warm transfer from the flame zone right into the unreacted strong.Propellants developed for a minimal warm transfer pressure may fail to sustain the fire area at reduced pressures., as well as acetyl cellulose.

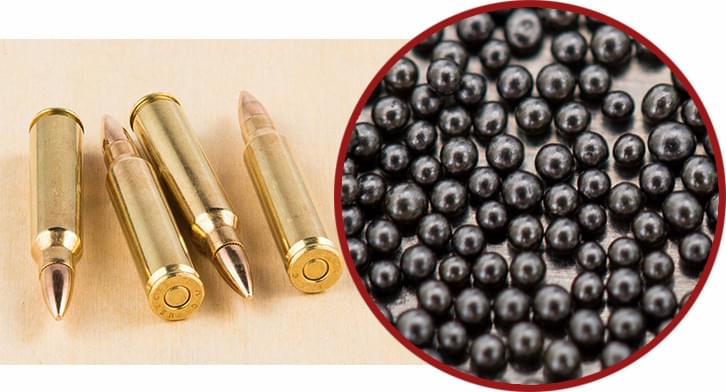

These include tin steel as well as compounds (e. g., tin dioxide), as well as bismuth steel as well as compounds (e. g., bismuth trioxide, bismuth subcarbonate, bismuth nitrate, bismuth antimonide); the bismuth compounds are favored as copper dissolves in molten bismuth, creating weak as well as conveniently detachable alloy. Lead foil and also lead compounds have been terminated because of poisoning. Large weapons make use of polyurethane coats over the powder bags. Various other ingredients consist of ethyl acetate (a solvent for manufacture of round powder), rosin (a surfactant to hold the grain shape of round powder) and graphite (a lubricating substance to cover the grains and also stop them from sticking, as well as to dissipate static electrical power). Before projectiles departure, a mild pre-flash might take place from gases leaking past the projectiles. Complying with muzzle exit, the heat of gases is generally sufficient to emit noticeable radiation: the primary flash. The gases broaden yet as they travel through the Mach disc, they are re-compressed to create an intermediate flash.

g. hydrogen and also carbon-monoxide) may comply with when they blend with oxygen in the bordering air to generate the additional flash, the brightest. The additional flash does not normally accompany little arms.: 5556 Nitrocellulose includes inadequate oxygen to completely oxidize its carbon and hydrogen. The oxygen deficiency is raised by enhancement of graphite and organic stabilizers.

The 3-Minute Rule for Imr Powder

At high temperature, these flammable gasses will stir up when turbulently combined with atmospheric oxygen beyond the muzzle of the weapon. During evening involvements, the flash produced by ignition can disclose the place of the gun to enemy pressures: 322323 and also cause temporary night-blindness amongst the weapon team by photo-bleaching visual purple.Artillery muzzle blink as much as 150 feet (46 m) from the muzzle has been observed, as well as can be mirrored off clouds and be visible for ranges approximately 30 miles (48 km).: 322323 For artillery, the most efficient technique is a propellant that generates a big proportion of inert nitrogen at relatively reduced temperatures that dilutes the combustible gases.

Prior to using he has a good point three-way based propellants, the usual method of flash reduction was to add not natural salts like potassium chloride so their specific warm capacity might minimize the temperature of combustion gasses and also their carefully separated particle smoke might obstruct visible wavelengths of radiant power of combustion.: 323327 All flash reducers have a drawback: the production of smoke.

These extrusions can be cut into short ("flakes") or long items ("cables" numerous inches long). Cannon powder has the biggest pieces.: 28: 41 The United States Navy produced single-base tubular powder for marine weapons at Indian Head, Maryland, beginning in 1900. Similar treatments were made use of for United States Army manufacturing at Picatinny Collection beginning in 1907: 297 and for manufacture of smaller grained Improved Armed force Rifle (IMR) powders after 1914. accurate powder.

Everything about Hodgdon Powder

The combination was then fed with a press squeezing out a lengthy tubular cable kind to be reduced right into grains of the preferred length.: 3135 Alcohol as well as ether were then evaporated from "eco-friendly" powder grains to a staying solvent concentration in between 3 percent for rifle powders as well as 7 percent for big weapons powder grains (https://publicate.it/p/rh00nqcj3sLi314059).

Grains were coated with electrically conductive graphite to lessen generation of fixed power during subsequent mixing. "Great deals" having even more than 10 tonnes of powder grains were mixed via a tower setup of mixing receptacles to lessen ballistic distinctions.

The Best Guide To Winchester Powder

Du, Pont. The Gun Zone. Retrieved 29 June 2013.Report this wiki page